How to operate the solar street light pulling line

by:SRS

2021-06-14

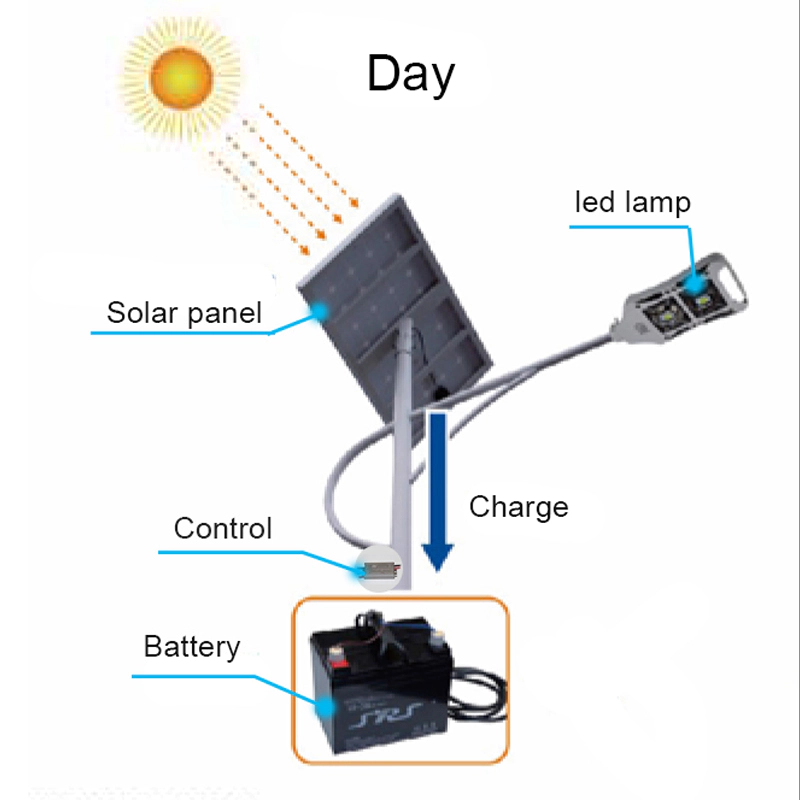

are not only suitable for use in big cities. In fact, solar street light are also very suitable for places with relatively small populations, underdeveloped economies and no power stations. Many customers are suitable for solar street light installation, and they don’t know much about the operation process of pulling lines. , Let the professionals answer for everyone below. 1. Insulated sheathed wire should be used for the vertical covered wire, the copper core should not be less than 1.37 mm, and the aluminum core should not be less than 1.76 mm. 2. It is best to overlap the two sides of the pole when the vertical leather wire is connected to the overhead conductor. The overlap should be 400mm to 600mm away from the pole, and the distance between the two sides should be kept the same. 3. After the vertical leather wire of the solar solar street light exceeds four meters, a support should be added in the middle to fix it, using no less than 7/1.0 insulated wire, and then using a single cross binding method for binding. 4. When the metal of the pole wire and the vertical wire are different, the phase-to-phase tying wire should be used as the jumper of the excessive joint. This kind of jumper should not exceed 100 mm, and it should be noted that the insulating support should be turned back. It can be wound with this wire. A plastic tube should be added to the gray pole or iron tube of the power cord. The length of the tube is not less than 200 mm. 5. When the vertical line of the transformer pole is too close to the high-voltage lead, 7/1.0 insulated stranded wire is required. After the back buckle is used at the link of the main trunk line, a tie wire should be used, and the winding is 30 to 50 mm. 6. The vertical line of the solar solar street light must be tied tightly, and the whole line must be suitable. If the vertical line is broken or bare, it should be replaced in time, and the vertical line and the household connection line should swing at the maximum, and the distance should not be less than 50 mm. , There is also the need to use pliers to tighten the jumper when connecting the vertical wire to the power supply during construction and maintenance. For capacitors and ballasts, each crimping screw can crimp at most two wire ends. The bending direction of the wire ends should be clockwise and pressed with flat pads. Solar street light pulling wire is also very important. If you don’t pull it well, you may encounter a lot of trouble in the future. If you want to know more information about solar solar street light, you can consult online customer service staff.

If you have a need for custom made solar lights solar light, like , and , you need to be able to find a dependable provider who you can trust when necessary.

Sky Resources Solar Technology Co.,ltd. is a reliable company that offers wonderful . In addition, the company also provides related components to make it more efficient. To know more, go to SRS Solar Street Light.

People tend to want what they perceive they cannot have. Making SRS seems exclusive or as if it will go out of stock if they don't act quickly often makes it more enticing to the consumer and increases the likelihood that they will buy in.

led street light manufacturers solar light is characterized by various advantages, such as custom made solar lights, led street light manufacturers and custom made solar lights, which is not the case with other solar light.

There are many advantages associated with .

If you have a need for custom made solar lights solar light, like , and , you need to be able to find a dependable provider who you can trust when necessary.

Sky Resources Solar Technology Co.,ltd. is a reliable company that offers wonderful . In addition, the company also provides related components to make it more efficient. To know more, go to SRS Solar Street Light.

People tend to want what they perceive they cannot have. Making SRS seems exclusive or as if it will go out of stock if they don't act quickly often makes it more enticing to the consumer and increases the likelihood that they will buy in.

led street light manufacturers solar light is characterized by various advantages, such as custom made solar lights, led street light manufacturers and custom made solar lights, which is not the case with other solar light.

There are many advantages associated with .

Custom message